-

-

-

-

Company Profile

Culture

Add:Liu Tuo Ying industrial zone, Boye County, Hebei province

Tel:+86 15033266555

Quote Now

Solutions for Your Industry, Ready for Your Choice

+

+- Description

-

Uses

The heat-resistant conveyor belt is mainly used for conveying high-temperature materials, such as sinter hot coke, cement clinker, hot castings, etc. According to the main performance of heat-resistant belt damage and loss of conveying capacity and different heat-resistant levels, EPDM or SBR are used as covering rubber respectively. High-strength and high-permeability polyester canvas or cotton canvas is used as strong layer. Heat-resistant glass cloth can be laid between the covering glue and the skeleton to improve the service life of the heat-resistant belt. According to customer requirements, can be made into a ring belt.

Heat resistant and high temperature resistant conveyor belt is widely used in coal, mining, port, metallurgy, electric power, chemical industry and other fields to transport materials.

Features

1. High strength, thin belt and light weight.

2. Use EP dipped canvas as skeleton material.

3. The belt body is soft, the groove is better, and the elasticity is better.

4. Impact resistance, wear resistance, corrosion resistance.

5. Adapt to large load, fast speed and medium and long distance material transportation.

6. Smooth operation, no deviation.Specifications and technical parameters

Specifications and Technical Parameters of Polyester Multilayer Conveyor Belt Fabric

TypeFabric construction Fabric type Thickness of adhesive tape Strength series (N/mm) Cover glue thickness

(Mm)Width

Scope

(mm)

By Weft Layer 2 Layer 3 4 floors Upper cover glue Lower cover glue Polyester

(EP)Polyester cotton nylon EP-80 1.00 160 240 320 0-12 0-10 300-2500 EP-100 1.00 200 300 400 EP-125 1.05 250 375 500 EP-150 1.10 300 450 600 EP-170 1.10 340 510 680 EP-200 1.20 400 600 800 EP-250 1.40 500 750 1000 EP-300 1.60 600 900 1200 EP-350 1.70 1050 1400 EP-400 1.90 1600 EP-500 2.10 2000 Adhesive strength, elongation performance in accordance with the following table

Adhesion strength, elongation performance with core

Materialsbond strength Extension performance Interlayer N ≥ mm Covering layer and layer

N/mmFull thickness longitudinal elongation at break Full thickness longitudinal reference force elongation Covering layer thickness ≤ 1.5mm Covering layer thickness ≥ 1.5mm Polyester Canvas ≥ 5 ≥ 4.5 ≥ 5 ≥ 10% ≤ 4% The covering performance of the 5. tape shall comply with the following table

Covering performance of tape Overlay Level Tensile strength Elongation at break Abrasion Change rate of tensile strength and elongation at break after aging Mpa Kgf/cm2 % mm3 % H 24 240 450 120 -25 ~ 25 D 18 180 400 100 -25 ~ 25 L 15 150 350 200 -25 ~ 25 The physical and mechanical properties of the 5. heat resistant coating after the heat resistance test shall meet the requirements of the following table

Project Model T1 T2 T3 T4 Range of change Hardness Difference between after aging and before aging 20 20 ±20 ±20 Larger value after aging 85 Tensile strength Minimum value after aging 12 10 5 5 Performance change rate/% -25 -30 -40 -40 Elongation at break Performance change rate/% -50 -50 -55 -55 Minimum value after aging 200 200 180 180 German Standard DIN-22102 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm W 18 400 90 ≥ 5 3.5 4.5 X 25 450 120 Y 20 400 150 Z 15 350 250 English Standard BS 490 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm M 24 450 - ≥ 5.25 3.15 4.5 N 17 400 - Australian Standard AS 1332-2000 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesion strength between cover layer and cloth layer (/mm) Covering layer thickness 0.8~1.5mm Cover layer thickness> 1.5mm A 17 400 70 6 4 4.8 E 14 300 - F 14 300 - M 24 450 125 N 17 400 200 S 14 300 250 S* 12 300 250 South Africa SANS 1173:2005 Grade Tensile strength ≥ Ma Elongation at break ≥ M% Abrasion ≥ mm3 Adhesion strength between layers of cloth (N/mm) Adhesive strength between cover layer and cloth layer (N/mm) A 18 400 90 ≥ 7 ≥ 5 X 25 450 120 M 24 450 150 N 20 400 250 Specification and Technical Parameters of Nylon Multilayer Fabric Core Conveyor Belt

Fabric Type Fabric construction Fabric type Thickness of adhesive tape (mm/p) Strength series (N/mm) Cover glue thickness Width range (mm) By Weft Layer 2 Layer 3 4 floors 5 floors 6 layers Upper covering layer Lower cover Nylon cotton nylon cotton nylon Nn-100 1.00 200 300 400 500 600 0-12 0-10 300-2500 Nn-125 1.05 250 375 500 625 750 Nn-150 1.10 300 450 600 750 900 Nn-200 1.20 400 600 800 1000 1200 Nn-250 1.40 500 750 1000 1250 1500 Nn-300 1.60 600 900 1200 1500 1800 Adhesive strength, elongation performance in accordance with the following table

Adhesion strength, elongation performance Core material bond strength Extension performance Interlayer N/mm Covering layer and layer N/mm Full thickness longitudinal elongation at break Full thickness longitudinal reference force elongation Covering layer thickness ≤ 1.5mm Covering layer thickness ≥ 1.5mm Polyester Canvas ≥ 5 ≥ 4.5 ≥ 5 ≥ 10% ≤ 4% 6 The covering performance of the tape is in accordance with the following table

Covering performance of tape Overlay Level Tensile strength Elongation at break Abrasion Change rate of tensile strength and elongation at break after aging Mpa Kgf/cm2 % mm3 % H ≥ 24 ≥ 240 ≥ 450 ≤ 120 -25~ 25 D ≥ 18 180 ≥ 400 ≤100 -25~ 25 L ≥ 15 150 ≥ 350 ≤200 -25~ 25 Application Real Scene

Honor

Providing Our Customers with Best Services

Served over 300 customers from 60 countries

Our products are popular in China and exported to Europe, America, Japan, South Korea, Australia, the Middle East, Africa, Southeast Asia and other countries and regions. Our goal is to sincerely cooperate with domestic and foreign customers for mutual benefit and establish good business trade relationships.Our professional R&D team is committed to the innovative development of efficient and high-quality conveyor belt products.

FAQ

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

Can I take samples for testing?

Yes, samples can be sent for testing before bulk ordering.

Do you have pre-shipment inspection procedures?

Yes, we always test the products before delivery.

Introduce

Boye County Tairui industrial and Mining Machinery Manufacturing Co., Ltd was founded in 2012, is a research and development, design, production, sales as one of the professional machinery manufacturing company. The registered capital of the company is 20 million yuan, located in Boye County Economic Development Zone.

Boye County Tairui industrial and Mining Machinery Manufacturing Co., Ltd is fully equipped, the use of domestic advanced technology automated production line, is the most comprehensive transportation machinery and accessories sales enterprises. The company's main products are six series of products: wheel series, drum series, bracket series, conveyor belt series, conveyor equipment and accessories.

Previous

+

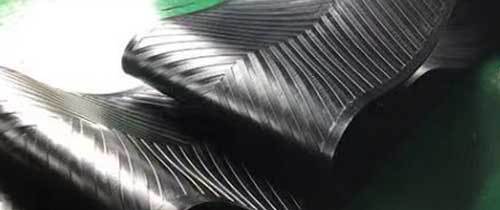

+High temperature resistant conveyor belt

The heat-resistant conveyor belt is mainly used for conveying high-temperature materials, such as sinter hot coke, cement clinker, hot castings, etc.The company's product color, size can be customized according to demand, if there is demand, please contact us!

subcategory

keyword

Telephone/WhatsApp:

E-mail:

INQUIRY

Business License

-